In the first part, we talked about four PCB marks: stamp holes, a specific type of holes, solder thief pad and fiducial marks. Today, we’re going to take a look at another four common marks. So let’s get started.

From Right to Left: Fuse Traces, Spark Gaps, PCB Buttons and PCB Slots

From Right to Left: Fuse Traces, Spark Gaps, PCB Buttons and PCB Slots

Spark Gap

Image Courtesy of Jumperone

Image Courtesy of Jumperone

It’s for ESD, current surges and over voltage protection. The high voltage will ionize the air between the two terminals and a spark will form across them before it damages the rest of the circuit. It’s not advised to use this way of protection, but it’s better than nothing.

According to an issue published by Microchip, the main drawback is that performance can change over time. The breakdown voltage can be calculated with the following formula V=((3000×p×d)+1350), where “p” is the pressure in atmospheres and “d” is the distance in millimetres.

For more information about spark gaps, you definitely need to watch Dave’s 20-min-long video about spark gaps (it includes real experiments).

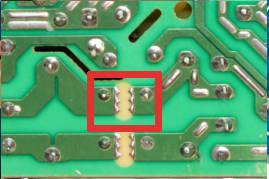

PCB Conductive Button

Image Courtesy of maximilian009

Image Courtesy of maximilian009

If you have ever torn down a remote control or a calculator, then you should see like this pad. It consists of two interleaved terminals (but not connected). When the rubber button from the keypad is pressed it will cause the two terminals to be connected, since the bottom of this rubber buttons is conductive. You can find this PCB button in Sparkfun Eagle CAD library (SparkFun-Switches) or you can build your own custom-shaped pad in Altium.

then you should see like this pad. It consists of two interleaved terminals (but not connected). When the rubber button from the keypad is pressed it will cause the two terminals to be connected, since the bottom of this rubber buttons is conductive. You can find this PCB button in Sparkfun Eagle CAD library (SparkFun-Switches) or you can build your own custom-shaped pad in Altium.

Fuse Trace

Image Courtesy of Samuel

Image Courtesy of Samuel

Similar to the Spark Gap, this is another cheap technique using PCB. The fuse trace is a necked trace on the power line, and it’s a one-shot fuse. The same configuration can be used as a PCB jumper to remove a certain connection by simply etching the necked trace (the PCB jumper can be found in some Arduino UNO boards on the Reset line). To know more about the downsides of using a fuse trace, read this related question on StackExchange.

Slots

Image Courtesy of Jumperone

Image Courtesy of Jumperone

If you look into a high voltage device PCB like power supply, probably you will notice some air slots between some traces.

Repeated temporary electrical arcs in a PCB causes the carbonation of the PCB, which leads to a short circuit. To this end, a routed slots can be added in suspected areas, where arcs can still occur but nothing will be carbonized.

Is there any other mark, you have seen, and never know why it’s there? Mention it in a comment please .

What are Fiducials? And when and how do we use them on PCB?

They are used to calibrate the computer vision of some assembling machines like PnP. You can ask your manufacture for guidelines on where and how many points to add. I read a rule-of-thumb said that 3 of them in different places in the board is enough.

hi

i searched very much for my SG mark on my gw-instek multimeter (i think it is a varistor or spark gap, but i’m not sure) at the V/ohm entrance terminal’ and i didn’t find any schematic for that

Hi,

Arcing is exceptional and is generally never allowed anywhere except in specific locations called spark-gaps.

Slots are then cut to increase the resistance to arcing when there isn’t enough distance between conductors across a surface.

They increase the Creepage distance and increase the resistance to an arc conducting across the PCB surface through contamination and humidity. An arc then either has to jump the slot or go around the ends. This increases the voltage required to arc; the increase must be enough that arcing never happens at that location.

The idea is that the air-gap, if large enough, can’t be contaminated and will always be an air-gap. Conductor separation by air-gaps is considered Clearance and can be closer than separation across a surface and subject to Creepage rules.

Thanks for you valuable input!

i see the PCB Conductive Button you mention in my gamepad and another button but it have a pressure trigger, what is that pcb button??